About Us

Pillai Group is located in Kolhapur, Maharashtra, India. Kolhapur is one of the five major foundry clusters in India. The Kolhapur foundry cluster is renowned for its automotive castings.

Pillai Group

In a visionary endeavour, Mr. M. N. Pillai, a founding luminary of our esteemed group, embarked on a transformative journey in 1980, igniting the genesis of Geeta Pumps. With audacious ambition, he established a Cupola Furnace dedicated to the craftsmanship of Grey Cast Iron, complemented by a sophisticated machine shop. This bold inception bore fruit with Geeta Pumps emerging as a manufacturing powerhouse, boasting a monthly production capacity of 500 metric tons of meticulously machined castings.

In 1993, the saga of innovation continued as we charted a course toward excellence. The introduction of an Induction Furnace and the establishment of a cutting-edge machine shop under the banner of M/s. Neeta Instruments heralded a new era of capacity expansion and technological advancement.

Fast forward to May 2013, a pivotal chapter in our illustrious history unfolded with the birth of Riddhi Casting Pvt Ltd. Here, the pursuit of excellence reached its zenith with the implementation of a fully automated sand plant, three state-of-the-art Melting Induction Furnaces, and the crowning jewel—a Fully Automated Disa moulding line. This visionary endeavour catapulted our production capacity to an astonishing 1100 metric tons of premium-quality castings each month, reaffirming our unwavering commitment to delivering excellence at every turn.

Our Expertise

Manufactures 100% Ductile Iron

We specialize in the Manufacturing of 100% Ductile Iron components across all grades. Our expertise extends to producing precision-machined components for a wide range of applications, including automotive, non-automotive & off-highway.

International Excellence

Our state-of-the-art manufacturing facility employs cutting-edge techniques to produce every component. Whether it's a single part or a complex assembly, we consistently deliver excellence through precision machining.

Green Practices and Advanced Manufacturing

Our advanced manufacturing facility is integrated with ERP and MIS to ensure that present process control parameters are maintained and monitored closely. This team ensures first-time-right quality. Also, the sand system of this foundry is fully automated and 100% recycled.

Hub, Trumpets, Planetary Carriers & Differential Cases

A core area of expertise lies in crafting essential components like Hubs, Trumpets, Planetary Carriers, and Differential Cases, which play a crucial role in machinery performance. Our dedicated and highly skilled team ensures their precise and reliable production.

Insightful Leadership

Mr. M. N. Pillai Chairman (BE Mechanical) Finance, Overall Management

Mr. Anukumar Pillai Managing Director BE (Mechanical) , MBA (Finance) Operations & Marketing

Mr. Rishabh Pillai Director BE (Mechanical), MBA (Finance-Baruch College, New York)

Quality Policy

Our quality policy commits us to maintain the highest standards of product excellence and customer satisfaction by adhering to stringent quality control processes and continuously improving our operations to meet evolving customer needs.

Pillai Group of industries is continually striving for achieving better quality of product, safery related products, supply at right time and at right price in order to delight the customer

Quality Objectives

Improvement in Customer Satisfaction:We constantly refine our products and services, actively seeking and acting on customer feedback, and setting higher standards.

Reduce rejection % :We reduce rejection rates by implementing stringent quality control measures, process enhancements, and employee training.

On-time Delivery: We always ensure customers receive their orders promptly and fostering trust and reliability in our services.

Vision

Our vision is to be world class supplier of Ductile Iron Components in Supplying intricate and safety machined components parts by,

By providing products and services that exceed customer expectations.

By leveraging our knowledge base to provide customers with value enhancement opportunities.

By developing technological skills and process skills to gain competitive advantage

Mission

Our goal is to become highly skilled in foundry and machining technology while adhering to honest and ethical business practices. We aim to efficiently use the resources at our disposal to achieve the highest levels of productivity, efficiency, and profitability.

Additionally, we are dedicated to prioritizing the long-term interests of our stakeholders, ensuring a promising and sustainable future for all.

IATF 16949

ISO 9001:2015

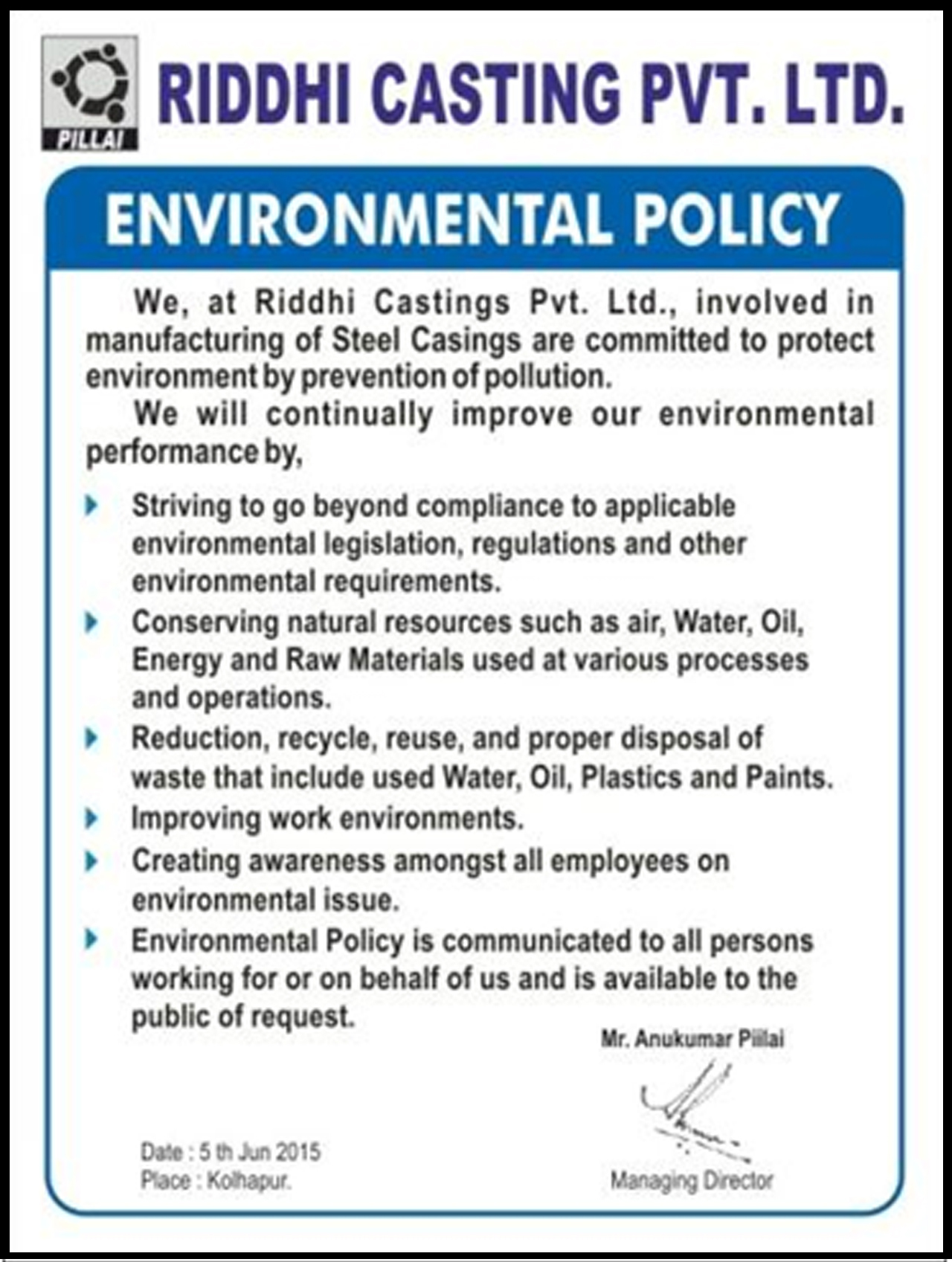

ENVIRONMENTAL POLICY

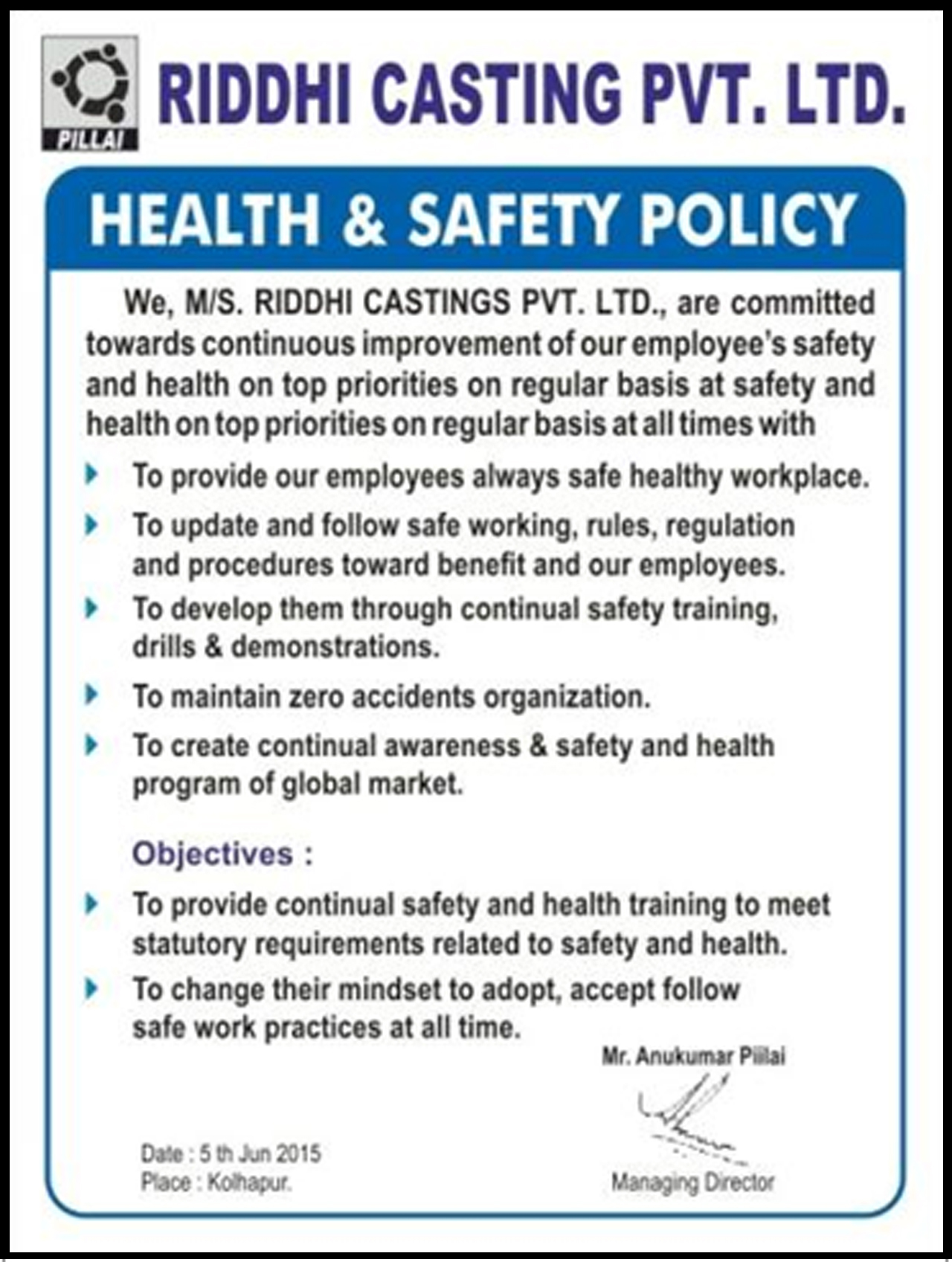

HEALTH & SAFETY POLICY

Our Esteemed Customers

Infrastructure

Foundry

Infrastructure

Machine Shop

Riddhi Casting Pvt. ltd., Plot No.107-111 & 120-124, K.A.Co.Op.Ind.Estate, Tardal-Hatkanangale, Kolhapur-416 121. Maharashtra, India.

anukumar@pillai-group.com

+91 9860742225, +91 7722047575

Neeta Instrumets A - 12/13 , Shiroli MIDC, Kolhapur - 416122 Maharashtra, India

amit@pillai-group.com

+91 9860822555

Geeta Pumps Pvt. Ltd. B - 17 , Shiroli MIDC, Kolhapur - 416122 Maharashtra, India

anukumar@pillai-group.com

+91 9860742225